A VFD centrifuge is a centrifugal separation machine that uses a Variable Frequency Drive (VFD) to control its motor speed, acceleration, and deceleration with high precision. This setup brings a significant upgrade compared to traditional fixed-speed centrifuges. By adjusting the frequency and voltage supplied to the motor, the VFD enables smooth and customizable operation, which is especially useful in processes where the separation quality depends on precise rotational speed or when handling different types of materials. In traditional centrifuges, starting the machine at full speed can cause mechanical stress, high inrush current, and faster wear and tear. With a VFD, the motor starts gently with a soft start, gradually increasing the speed, reducing mechanical shock, and prolonging the life of the equipment.

Applications of VFD Centrifuges

The Precision Speed Control for Centrifuges system uses advanced Variable Frequency Drive (VFD) technology to provide smooth, adjustable, and energy-efficient control of centrifuge speeds. By precisely managing motor frequency and voltage, it ensures optimal performance, reduced mechanical stress, and significant energy savings.

Optimized Speed Management involves the intelligent control and adjustment of system or equipment speeds to maximize performance, efficiency, and safety.

Reduces energy consumption by adjusting motor output to match the required load, cutting operational costs.

Smooth Start and Stop refers to the controlled acceleration and deceleration of machinery and systems to prevent mechanical stress.

Protects equipment with built-in features like overload protection and fault diagnostics, along with temperature monitoring.

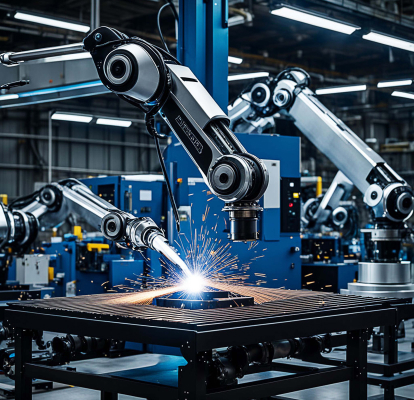

Our Industrial Automation and Robotics planning and strategy services focus on designing tailored automation solutions that align with your business goals.

A VFD allows precise control of motor speed and torque, enabling optimized separation performance, energy savings, and reduced mechanical wear in centrifuge applications.

Yes! By adjusting the motor speed to the exact process requirements, a VFD significantly reduces energy consumption and lowers operational costs.

Absolutely. VFDs provide smooth acceleration and deceleration, which minimizes mechanical stress and extends the service life of the centrifuge components.

Yes, modern VFDs come with advanced safety features like overload protection, short-circuit detection, and emergency stop functions to ensure safe operation.

Yes, VFDs can be connected to monitoring systems that provide real-time data on performance, faults, and maintenance needs for proactive management.

CIN -U27331TN2024PLC173781

PAN - AAHCH5637G

Copyright © 2025 All Rights Reserved By Hertson.