An Auto Cane Feeding System is an automated setup used in sugar mills to efficiently and uniformly feed sugarcane from the unloading area (like truck tippers) to the crusher or milling tandem.Instead of manual feeding or uncontrolled bulk dumping, the system uses mechanical and electrical automation to control the flow, speed, and consistency of cane fed into the mill. This results in better milling performance, higher juice extraction, and less wastage.

Where It’s Used

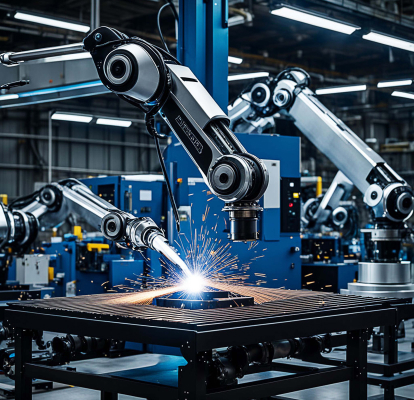

The Smart Cane Feeding System is an advanced solution engineered to automate and optimize the process of feeding sugarcane into crushing units. By ensuring consistent material flow and reducing manual intervention, the system improves operational efficiency, boosts sugar recovery rates, and promotes safer working conditions.

The system dynamically regulates the feeding rate of sugarcane, maintaining an even and controlled flow to the crushing unit.

Labor Efficiency Boost refers to the automation and optimization of processes that reduce manual workload, streamline operations.

High-Performance Output ensures maximum efficiency, power, precision across operations. Designed to deliver superior results even under demanding conditions.

Engineered with maintenance in mind, the system features accessible components and straightforward diagnostic tools.

The Automated Cane Handling System is an advanced solution designed to automate the feeding of sugarcane into processing units, ensuring smooth operation, increased productivity, and enhanced worker safety.

It is an advanced system designed to automatically feed sugarcane into processing units, ensuring continuous flow, improving operational efficiency, and reducing the need for manual labor

By providing a steady and controlled supply of sugarcane, the system optimizes crusher performance, minimizes downtime, and increases overall throughput, leading to higher sugar recovery rates.

Yes, the system is designed to integrate seamlessly with most existing sugar mill equipment. It can work alongside crushers, conveyors, and automation controls to enhance overall plant operations.

The system includes emergency stop functions, overload protection, and automated shutdown in case of blockages, reducing risks for operators and equipment.

Thanks to its robust design and easy-access components, the system requires minimal maintenance. Routine inspections and timely servicing will ensure long-term reliable performance.

CIN -U27331TN2024PLC173781

PAN - AAHCH5637G

Copyright © 2025 All Rights Reserved By Hertson.