A DC mill drive refers to a system that uses a DC motor (Direct Current motor) to drive a mechanical load, often in industrial settings such as in rolling mills, mining, or similar processes where large-scale mechanical work is done. DC motors are commonly used because of their excellent control over speed and torque.

Recent Trends and Replacements:

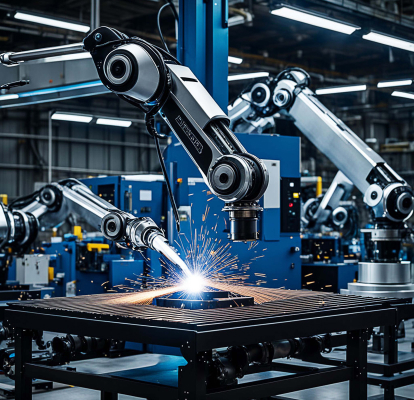

He High-Performance DC Drive for Milling Applications offers robust and precise control for a variety of industrial milling operations. Specially designed to manage high torque and dynamic loads, this system enhances productivity, ensures smooth mill operation, and extends equipment life.

Delivers powerful torque at low speeds, crucial for heavy milling operations. This ensures smooth starts, consistent operation under varying loads.

Maintains consistent output even under fluctuating power conditions or load changes. The system’s keeps milling processes running without interruptions.

Built to reduce power consumption without sacrificing output. The efficient design helps lower operating costs while supporting sustainable production goals.

Equipped with intuitive controls and real-time monitoring, making it easy for operators to adjust settings, and carry out maintenance efficiently.

The Industrial DC Drive Solution for Mills is a powerful and efficient drive system built for the demanding environments of industrial milling operations. With advanced control technology and high torque output, it ensures smooth, precise, and energy-efficient performance.

A DC drive controls the speed and torque of DC motors in milling machines. It ensures precise control, smooth operation, and consistent performance under variable load conditions, which is essential for industrial milling processes.

Yes! The DC drive is designed specifically for heavy-duty environments like steel rolling mills, paper mills, and other industrial settings where high torque and rugged performance are required.

The drive optimizes power usage by adjusting motor speed and torque according to the load, significantly reducing energy consumption and lowering operational costs.

Absolutely. The drive features accessible components, built-in diagnostics, and predictive maintenance alerts, making routine maintenance simple and minimizing unexpected downtime.

The system includes multiple safety features such as overload protection, short-circuit protection, emergency stop functionality, and real-time fault monitoring to ensure safe and reliable operation.

CIN -U27331TN2024PLC173781

PAN - AAHCH5637G

Copyright © 2025 All Rights Reserved By Hertson.