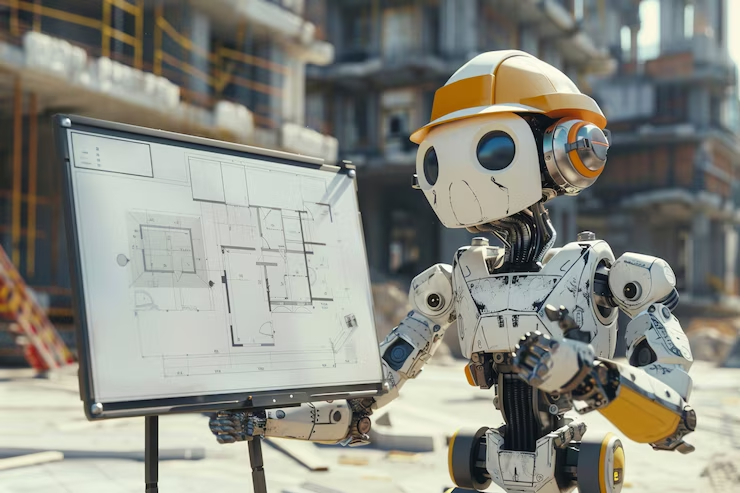

At Hertson Company, we specialize in providing innovative and reliable control systems that help optimize production processes across various industries. Our advanced control systems are tailored to meet the unique demands of the cement manufacturing industry, ensuring seamless operations, enhanced safety, and improved efficiency.

Our systems offer real-time monitoring of temperature, pressure, and flow rates throughout key stages of cement production, including raw material grinding, kiln operation, and cement milling.

Our control systems provide detailed analytics and reporting, offering valuable insights into production trends, equipment performance, and potential areas for improvement.

Grinding is a critical stage in cement production, and efficient mill control can significantly impact overall productivity. Hertson’s control systems for cement mills ensure high performance, energy efficiency, and consistent product quality.

Once the cement is produced, our control systems manage the packaging and dispatch processes, ensuring products are handled efficiently and accurately.

With years of experience in the cement industry, our control systems are specifically designed to optimize each stage of the production process, improving efficiency and quality.

We offer state-of-the-art technologies that are customizable and scalable to meet the unique needs of cement manufacturers, whether you’re a small producer or a large multinational.

Our control systems are built to optimize energy usage, reduce waste, and support environmentally sustainable manufacturing practices.

Hertson provides ongoing support, training, and maintenance services to ensure your control systems are always running at peak performance.

Whether you are looking to upgrade your current systems or implement new automation solutions, Hertson Company offers the control systems and expertise you need to streamline your cement production. Contact us today to learn more about how our control systems can help optimize your operations, reduce costs, and increase production efficiency.

CIN -U27331TN2024PLC173781

PAN - AAHCH5637G

Copyright © 2025 All Rights Reserved By Hertson.